Performance Proven by Neutron Diffraction Analysis from HANARO,

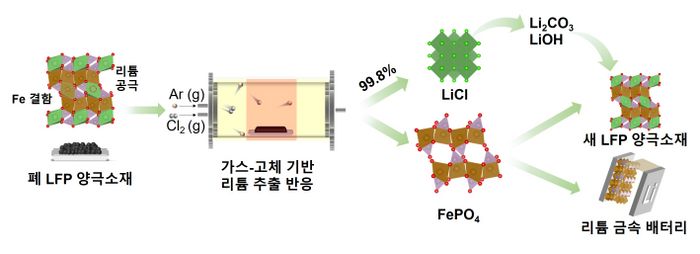

The Korea Atomic Energy Research Institute has developed a recycling technology for lithium iron phosphate (LFP) batteries. ©Korea Atomic Energy Research Institute, ‘[Dailyan = Reporter Kim So-hee] The Korea Atomic Energy Research Institute announced on the 10th that it succeeded in developing a new process to economically and environmentally recycle lithium iron phosphate (LFP) batteries used in electric vehicles.’,

,

, ‘LFP batteries use lithium iron phosphate as the cathode material and graphite as the anode material, differing from traditional lithium-ion batteries only in the cathode material. Due to the chemical properties of lithium iron phosphate, oxygen emission is suppressed, significantly reducing the risk of fire and explosion, which is why they are increasingly used in electric vehicle batteries.’,

,

, ‘However, when processing LFP batteries with the traditional battery recycling method using acid solutions, the only recoverable raw material is lithium (Li), making it economically disadvantageous. Moreover, a large amount of acidic waste solution is produced, posing environmental pollution issues.’,

,

, ‘In response, Dr. Hyeong-seop Kim’s neutron science team at the Atomic Energy Research Institute developed a process using chlorine (Cl2) gas to economically and environmentally extract the cathode material from LFP batteries.’,

,

, ‘When the powdered cathode material from decomposed LFP waste batteries is reacted with chlorine gas at 200°C for 10 minutes, lithium is extracted in the form of lithium chloride (LiCl). Lithium chloride can be converted back to lithium carbonate (Li2CO3) or lithium hydroxide (LiOH) through commercial conversion processes and reused as a raw material for synthesizing new LFP battery cathodes.’,

,

, ‘The iron phosphate (FePO4) in the cathode material was previously irreparably damaged by traditional acidic solution methods, making recycling impossible. However, this technology causes minimal damage, allowing for recomposition into LFP battery cathodes or use in next-generation lithium metal battery materials, enhancing economic feasibility.’,

,

, ‘Additionally, the by-products from this recycling process are in the form of brine (NaCl), which is much more environmentally friendly compared to the acidic waste produced by conventional methods.’,

,

, ‘To verify the performance of this process, the research team conducted precise analysis of the materials using the neutron diffraction analysis device of HANARO, Korea’s only research reactor.’,

,

, ‘As a result, 99.8% of the lithium in the LFP batteries was extracted, and the purity of the extracted lithium was confirmed to be a very high 98.8% efficiency.’,

,

, ‘Jung Young-wook, director of the HANARO Quantum Science Research Center at the Atomic Energy Research Institute, stated, “As the market share of LFP batteries increases, the impact of this recycling technology will be significant,” and added, “We will continue to make efforts to improve battery waste diagnosis and recycling processes using neutrons in the future.”\n’]